MAXSCAV™ : Low cost H2S scavenging in Asphalt and Bitumen

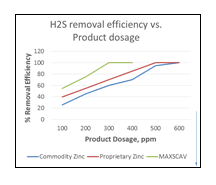

MAXSCAV™ has broken cost performance barriers for H2S scavenging in asphalt. MAXSCAV breakthrough technology increases the efficiency of organometallic zinc based scavengers and cost effectively extends the benefits of amine H2S scavenging to asphalt.

Dorf Ketal’s proprietary organometallic scavenger, MAXSCAV SR 1904 helps refiners and terminal operators safely reduce high levels of H2S in asphalt at up to 35% lower chemical cost. This new chemistry is based upon established organometallic mechanisms with proprietary formulation chemistry to deliver the same H2S scavenging power at 15% to 35% lower dosage. It addresses increasing safety concerns and produces a stable bitumen product with minimal potential for further release of H2S upon additional thermal stress.

MAXSCAV SR 1904 has higher activity than other organometallic scavengers which means customers use 15% to 35% less product. Refiners and terminal operators save more money.

MEA Triazine is not cost effective in H2S scavenging in asphalt and certainly not capable of performance at temperatures common to asphalt. MAXSCAV MEA Triazine has broken this temperature technology barrier and eliminates retreatment following the use of PPA to make performance grade asphalt products.

|

Gulf Coast VR Sample |

Product Dosage, PPM |

Final H2S PPM |

Final H2S PPM after PPA Addition |

|

Blank |

- |

26,000 |

+ 3,500 |

|

Proprietary Zinc |

5,000 |

< 10 |

30,000 |

|

MAXSCAV MEA |

5,000 |

< 10 |

< 10 |

Test results clearly demonstrate the effectiveness of MAXSCAV. Treatment at 1900C (3740F) for 15 minutes and 1770C (3500F) for 48 hours, both before and after PPA addition. Think of these experiments as two sequential tests. The blank generated 26,000 ppm H2S after 48 hours. When we added acid and heated for an addition 48 hours, 3,500 ppm of additional H2S was generated. A total of 29,500 ppm H2S was generated. In all experiments, samples were nitrogen purged until there was no additional H2S detected. Total heat exposure was 96.5 hours.

Asphalt is the heaviest of refinery products and typically has the highest concentration of sulfur compounds, often exceeding 1% (10,000 ppm). Asphalt’s high Vapor:Liquid partition coefficient (400:1) means that H2S collects in the vapor phase. High temperature storage, high viscosity and high H2S concentrations combine to make asphalt challenging to treat. MAXSCAV™ technology has just made H2S scavenging in asphalt easier and more economical.

MSafely reduce your hydrogen sulfide scavenger costs.

Find out how we can help you succeed.

Contact Us