Insoform® and Insothane® products for wire coatings

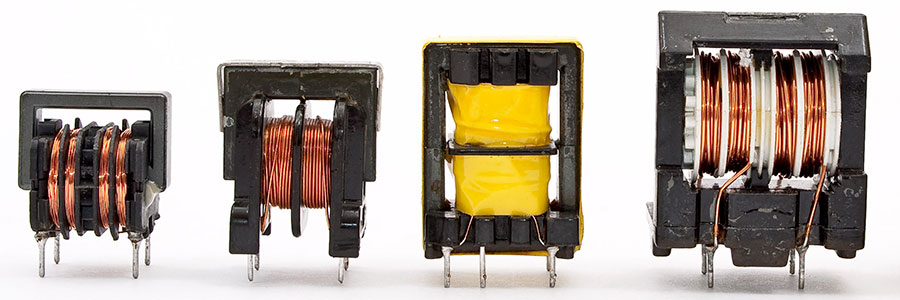

Insoform® products, chemically known as polyvinyl formal (PVF) are used in preparation of magnet wire or wire enamel coatings. Insoform® is combined with phenolic or other resins to produce an enamel coating which is applied under high temperature to round or rectangular section wire. Enamel coatings produced with Insoform exhibit excellent adhesion to the wire by crosslinking with the surface of the wire. The enamel coating delivers superior thermal, mechanical and electrical properties. These primary coatings provide electrical insulation preventing shorting of coils used in transformers. Coatings made with Insoform withstand high temperatures and retain their insulating properties to support transformer coils life expectancies of up to 40 years.

Insoform® is also used in manufacture of secondary coatings and insulation. The immersion of coils of enameled magnet wire in a bath of PVF based coating provides excellent moisture resistance upon drying. Other applications include use as a binder in magnetic tapes and as a surface coating to improve durability. Insoform can also be used as an ingredient in producing adhesives for structural applications.

Insothane® is a blocked poly-isocyanate product line used as an additive to produce solder-able wire enamels. Polyurethane enamel coated wires made from Insothane CT exhibit excellent thermal and mechanical properties.

Insothane® has excellent compatibility with many types of alkyds, polyesters, polyethers and polyacetal resins. Formulations made from combinations of these resins exhibit very good mechanical and electrical properties. Varnishes made with this resin have good hermetic properties.

Grow your business through innovation.

Find out how we can help you succeed within your industry.

Contact Us